Pressure Reducing Desuperheating Stations Manufacturers, Suppliers, Exporters in India,Maharashtra

Pressure Reducing Desuperheating Stations

Pressure Reducing Desuperheating Stations Manufacturers, Suppliers, Exporters in India,Maharashtra

Thermin Energy Systems Pvt. Ltd. is your source for Pressure Reducing Desuperheating Stations in India complete with piping and instrumentation. We are the Pressure Reducing Desuperheating Stations manufacturers, suppliers, exporters in India, Maharashtra.

Our Pressure Reducing Desuperheating Stations are supplied fully stocked and ready to fit into your pipes. Pre-assembled stations are individually sized to meet the specific needs of the end user. Steam pressure and temperature must decrease in various applications. Our Pressure Reducing Desuperheating Stations Exporters in India offer diverse range for such applications.

Inlet and outlet piping, as well as valves, are sized in accordance with best engineering practice. Each unit is custom designed and engineered to meet specific system requirements. Our stations are also easy to maintain.

Characteristics

- Precision Control: Pressure Reducing Desuperheating Stations systems provide precise control over steam temperature and pressure.

- Efficiency: They help maximize energy efficiency by maintaining optimal steam conditions.

- Safety: Ensures safe operation by preventing overheating or over-pressurization.

- Reliability: Designed for robust and reliable performance in industrial settings.

Introduction

A Pressure Reducing Desuperheating Station (PRDS) is a vital component in industrial processes that involve high-pressure steam systems. Its primary function is to reduce the pressure and temperature of superheated steam while also ensuring it becomes saturated. This is important because many industrial processes require steam at specific pressure and temperature conditions for optimal performance.

Common Types

- Attemperator: Uses a water spray to desuperheat steam.

- Control Valve: Modulates steam flow and water injection to control temperature.

- Combined PRV and Desuperheater: Integrates pressure reduction and temperature control in one unit.

How this Pressure Reducing Station Works?

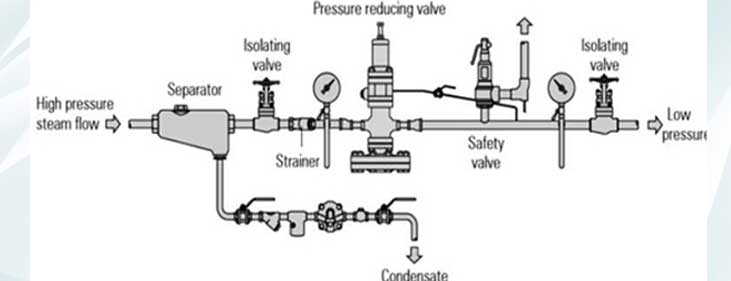

The Pressure Reducing Desuperheating Stations starts by reducing the high-pressure steam from the main steam line to a lower, specified pressure level. This is achieved byusing pressure-reducing valves (PRVs) or regulators.

Simultaneously, a desuperheating device, such as a spray water injection system or a control valve, introduces a controlled amount of water into the steam. This water mixes with the superheated steam, rapidly reducing its temperature and bringing it closer to saturation.

The goal is to achieve saturated steam, which is essential for various industrial processes. The PRDS carefully controls the water injection to ensure the desired temperature and pressures are achieved.

Industrial Uses

- PRDS stations are commonly found in power plants, chemical processes, refineries, and other industrial facilities where steam is a crucial component.

- They are essential for maintaining the desired steam conditions in processes such as turbine power generation, heating, and chemical reactions.

- It ensures the delivery of steam at precise pressure and temperature conditions for various industrial processes, thereby enhancing efficiency, safety, and reliability.